Operation Analysis and Control

Our operation analytics tool comes with sophisticated capabilities to understand the resource allocation to various processes, the current and future loading of departments and their capacities and alike. It gives the management perfect visibility of operation stress points and bottlenecks. We fully utilize the data from this tool to extend the capability in lead time prediction and supply chain planning. Imagine you operate lean on stocking, and you must figure out the lead time on every single out-of-stock product and there are hundreds of such queries daily. How many planners and analysts would you need? The tool as an example of its utility provides to the sales team a perfect visibility of items availability and flow and what to expect in future.

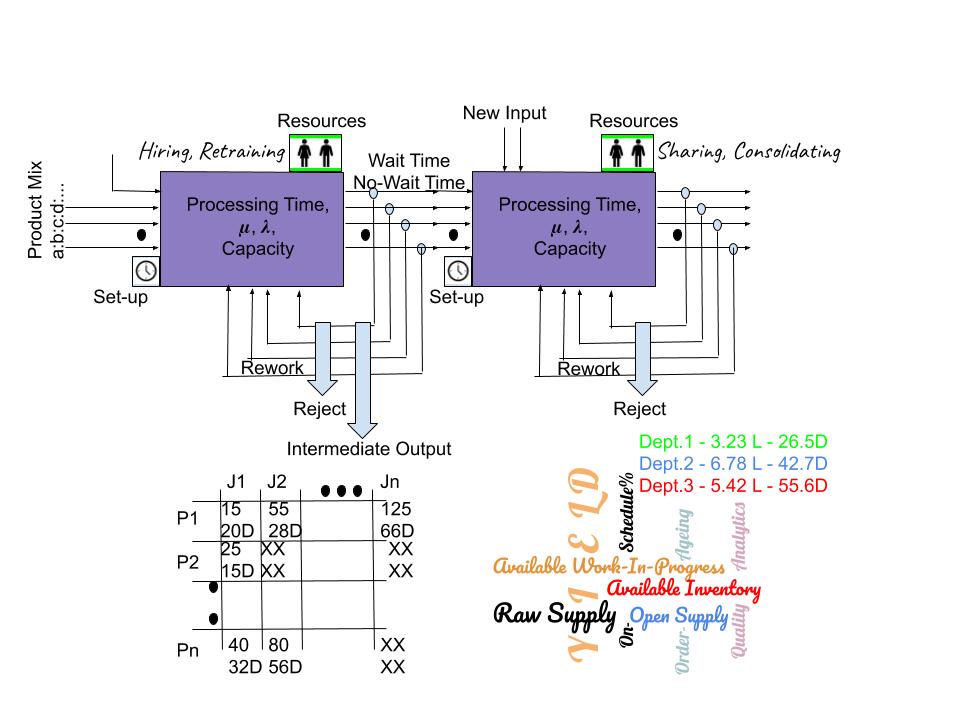

The tool can incorporate the functionality to understand the impact of hiring, retraining, resource sharing and process consolidation. You can only imagine how effortless the planning and resource allocation becomes when you know how your capacities are moving day-in and day-out. We highly encourage the management team to utilize this tool in budget preparation and team augmentation as well.

We also offer comprehensive operation performance analysis parameters for better control and transparency. Some of the examples can be yield analysis, reject analysis and other quality deviations as well as order ageing, on-schedule, suppliers’ risks and cycle/ wait time analysis. The parameters in this realm can be countless, it solely depends upon the business type and intent of the management. We can build to your requirement and advise you what other important parameters can make good sense to you.