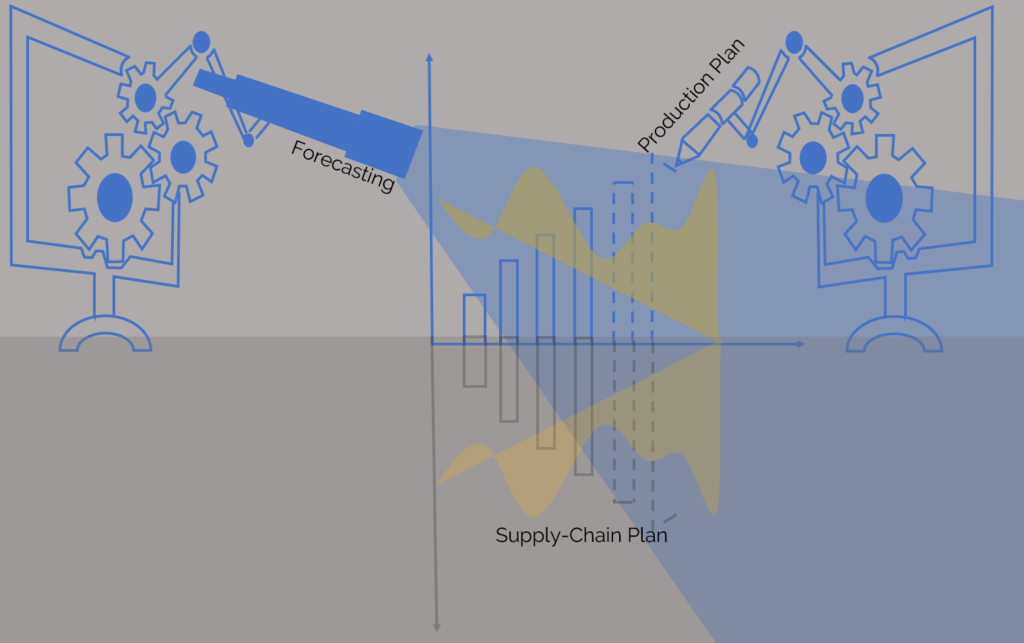

Forecasting and Planning

Every business faces the consequences of choices around stocking at a given level and at given point in time. Overstocking has much obvious consequences of losing money in markdowns, obsolescence, stocking-up & maintenance charges etc. Under-stocking leads to lost opportunity which may be more important for certain specific industries than others. Even more so, a continuous effort on war footing basis for production planning and supply chain team is hugely disturbing, leave aside the monetary loss arising out of chaos. Long lead times, higher costs, unbalanced utilization of resources and scraps can largely be avoided by proper understanding of demand and supply-chain as well as resource planning accordingly.

We offer comprehensive forecasting cum production planning tool which takes care of the demand variability and supply lead time variability without overstocking. We offer the tool to be implemented at finished product as well as at raw input level. We design this tool in a manner that it can be tested on past data to see how the results have been for performance parameters like stock-outs and inventory turnover. The tool is meant to respond to changing demand pattern and can be used to forecast next twelve months or more for proper production, resources and supply-chain planning. For perishable short-life items the tool comes with different functionalities. We highly encourage the production team to translate the forecasting and production suggestions into real life purchasing and production action. Special care is taken to cleanse the data to get intended results.